Functions

Vital part required to circulate coolant around engine. Heat produced by engine combustion is absorbed by coolant which then passes through radiator to cool down before returning to engine. Water pump is situated between radiator and engine and driven by pulley through timing belt or fan belt. Water pump causes coolant to circulate.

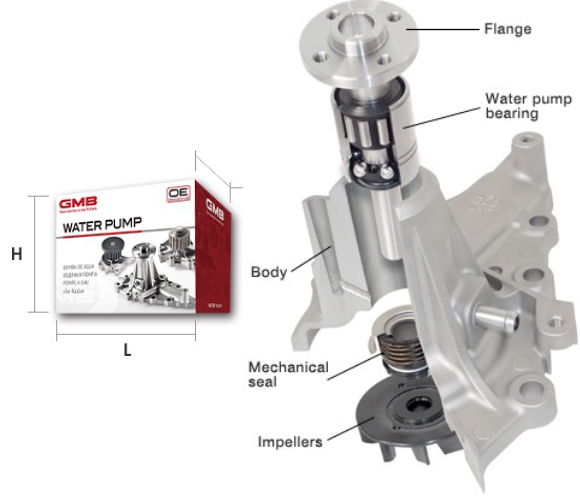

Structure

Consists of body (aluminum diecast, cast iron, aluminum gravity etc), flange(forged steel, sintered iron etc), impeller (pressed steel, cast iron, synthetic resin etc), water pump bearing and mechanical seal kit.

Its material is decided dependent upon performance level, quality as well as customer requirements and working conditions. Revolution power of crankshaft is transmitted to impeller through water pump bearing. Impeller vanes drive coolant out into circulation jacket.

Vortex chamber of water pump filled with coolant is separated from water pump bearing by mechanical seal kit.

A sliding seal, like mechanical seal kit, must be lubricated all the time it is moving by coolant fluid.

Engulfed(lubricating) coolant evaporates out into water pump bearing side and exits through weap hole on body.